Table of Contents

With the continuous development of agriculture, the types of agricultural machinery products are becoming more diversified and specialized. This has also brought new demands and requirements for the manufacturing of agricultural machinery products. Utilizing advanced laser processing technology, drafting systems, and CNC technology, laser cutting machines can not only reduce the production costs of agricultural machinery equipment but also improve economic efficiency.

Welding Requirements in the Agricultural Machinery Industry

As the agricultural machinery industry rapidly develops, the demand for high-precision and efficient production processes becomes increasingly prominent. Traditional cutting processes have limitations in meeting this demand, such as low processing accuracy and cumbersome processes. Meanwhile, there are many different types of sheet metal components in agricultural machinery products, and traditional manufacturing methods often use stamping machines, requiring a large number of molds. To reduce costs, many enterprises have started adopting more intelligent and efficient production methods, such as CNC machining and laser cutting. If parts are still processed using traditional methods, the update of products will be greatly limited, while adopting laser flexible processing technology can fully leverage its excellent characteristics.

Advantages of Laser Cutting Machine in the Agricultural Machinery Industry

Why is the laser cutting machine so popular in the manufacturing of agricultural machinery? The reasons lie in the powerful dynamic energy and cutting capabilities of the laser cutting machine, which has many advantages in agricultural machinery processing. Below, we will introduce the advantages of laser cutting machines in agricultural machinery production.

High Precision

Laser cutting machines use advanced laser control processing technology, achieving extremely high processing accuracy. For agricultural machinery parts that require special precision and specifications, laser cutting machines can ensure that the product quality meets standard requirements.

High Efficiency

Laser cutting machines have fast processing speeds. While ensuring processing accuracy, their production efficiency can be greatly improved. For the agricultural machinery industry, this means faster production speeds and better market competitiveness.

Material Adaptability

Laser cutting can be applied to various materials such as carbon steel, stainless steel, aluminum alloys, and more, offering great flexibility and adaptability.

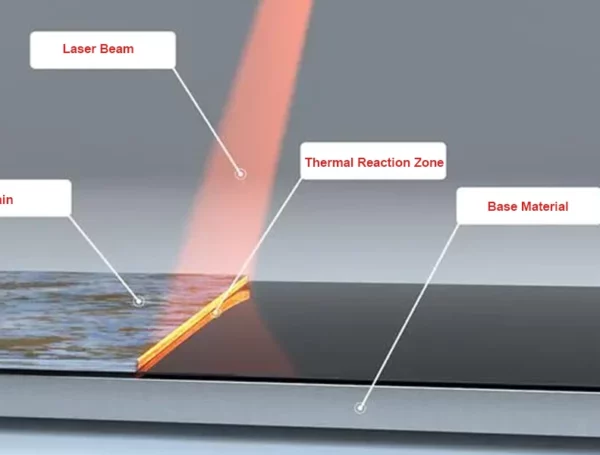

Non-contact Processing

Laser cutting is a non-contact processing method, which does not cause physical deformation or damage to materials, reducing wear and material waste caused by contact.

High Automation Level

Laser cutting machines can be operated through program control, allowing flexible processing of parts with different shapes and specifications, while improving the level of production automation.

Environmental Friendliness

Since the laser cutting machine's processing process uses laser processing technology, there are no harmful waste products produced. Therefore, compared to traditional processing methods, it is an environmentally friendly processing method.

Application of Laser Cutting Machine in the Agricultural Machinery Industry

The laser cutting machine is a high-tech product that can process various metal materials, such as carbon steel, stainless steel, aluminum alloys, copper, etc. It can also process materials of various shapes, such as round tubes, square tubes, flat iron, angle iron, etc. Due to its efficiency, high precision, and environmental advantages, it has gained increasing attention and application in various fields, with the agricultural machinery industry being one of its important application areas. Below, we will introduce the application of laser cutting machines in the agricultural machinery industry through several specific cases.

Farm Machinery

Laser cutting machines can process various models of farm machinery, such as tractors, trailed sprayers, and irrigation equipment. Especially for irrigation equipment, its pipes need to be precisely processed to ensure smooth water flow and accurate irrigation. Laser cutting machines, with high precision and high-speed characteristics, can meet these requirements, significantly improving the quality and efficiency of irrigation equipment.

Livestock Equipment

In recent years, with the continuous development of technology, the livestock industry has gradually transformed towards intelligent and information-based directions. Laser cutting machines can be used to manufacture livestock equipment, such as cow water feeders and feed troughs. Compared to traditional processing methods, laser cutting machines can more accurately process the required shapes and sizes, while ensuring the surface quality and cleanliness of the products.

Agricultural Machinery Components

Agricultural machinery components are an indispensable part of agricultural production, directly affecting the working performance and stability of agricultural machinery. Laser cutting machines can be used for the processing and manufacturing of various agricultural machinery components, such as pallets, couplings, sprockets, walking wheels, etc. Due to their high processing accuracy, they can improve the durability and stability of components.

Prospects of Laser Cutting Machine Application in the Agricultural Machinery Industry

With the continuous development of technology, the application prospects of laser cutting machines in the agricultural machinery industry are becoming broader. Especially in the direction of agricultural intelligence and informationization, the application of laser cutting machines will become more extensive, playing a crucial role in improving the efficiency and quality of agricultural production.

- Continuous Innovation in Laser Cutting Machine Technology: With technological development, the performance of laser cutting machines, such as power, cutting speed, and precision, will continue to improve, meeting the increasingly higher requirements of agricultural machinery manufacturing.

- Integration of Intelligent Manufacturing and Laser Cutting Technology: In the future, laser cutting technology will be more integrated with intelligent manufacturing technology, achieving a higher level of automation and intelligence in the production process.

- Laser Cutting of Multiple Materials: In the future, laser cutting technology will better adapt to various materials, including composite materials and new types of metal materials, enhancing its applicability in the agricultural machinery field.

- Integration of Laser Cutting Technology with Advanced Manufacturing Technologies: In the future, laser cutting technology will integrate with advanced manufacturing technologies such as 3D printing and machine learning, driving the agricultural machinery manufacturing into a new stage of development.

Conclusion

As an advanced manufacturing process, laser cutting technology has shown great potential and advantages in the agricultural machinery industry. Through high-precision and efficient cutting methods, laser cutting machines bring new development opportunities to the manufacturing of agricultural machinery. In the future, with continuous technological innovation, laser cutting technology will continue to drive the agricultural machinery industry to a higher level.