Transportation Industry

Characteristics and technical difficulties of the rail transportation (including trains) manufacturing industry

- Manufacturing characteristics

From the perspective of consumers and end-users, rail transportation and train manufacturing are evolving rapidly, including demand for greener, safer and technologically advanced trains. Currently, consumers are favoring trains with advanced safety systems and comfort features. Globally, the industry is facing stricter environmental and safety regulations.

- Technical specifications and technical difficulties

From a manufacturer’s point of view, responding to consumer and end-user needs and industry developments is a huge challenge. The rapid pace of technological change requires constant development of new technologies to meet industry standards and regulations. There is also a growing demand for high-quality raw materials, which puts some pressure on manufacturers. In the future, the industry is likely to face further technical difficulties, including further advances in intelligence and automation. Particularly in response to environmental requirements, European rail systems are moving in a more environmentally friendly direction, such as the use of more renewable energy and measures to reduce emissions. In addition, the increasing standardization of safety standards for high-speed railroads and metros will also bring greater challenges to the industry, and some countries have implemented more stringent safety standards, such as collision testing of trains and improvement of safety systems to reduce the likelihood of accidents.

Typical products and application cases

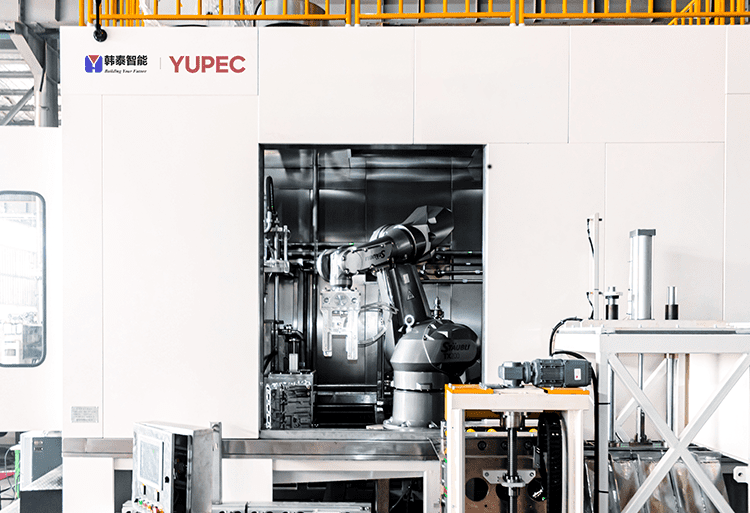

Robot Flexible Laser Cutting and Welding System

Integrality

- Difficulties : Efficient integration of laser cutting and welding systems into robot platforms for flexible and efficient production.

- Solutions : A highly customized automation control system enables the seamless integration of laser cutting and welding processes. In a previous case of a train car production line, the integration of this system successfully reduced the production time by 30%.

Precision control

- Difficulties : Realize high-precision laser cutting and welding to ensure product quality and safety.

- Solutions : Equipped with high-precision sensors and advanced control algorithms, the system can realize ±0.1mm precision control in the manufacture of train doors and other key components, ensuring the quality and safety of products.

Manufacture of train carriages

- Applications : The Robot Flexible Laser Cutting and Welding System was used in a metro vehicle manufacturing project to create the floor and roof of the vehicle. The system greatly improves the accuracy and efficiency of cutting and welding compared to traditional machining methods.

- Benefits : By adopting this system, the customer not only improved product quality, but also realized a significant increase in production efficiency, which enabled the project to proceed smoothly and on schedule.

Train door manufacturing

- Applications : In a high-speed railroad door manufacturing project, the system was used in the cutting and welding process of the door, which ensured the flatness and strength of the door and greatly improved the safety and service life of the door.

- Benefit : Thanks to the high precision and efficiency of the machining, the customer is able to guarantee the quality of the product while at the same time significantly reducing production costs and cycle times.

Line Pipe Laser Welding Connection System

Efficient integration

- Difficulties : Efficient integration of the laser welding system into the forming line and its use to continuously laser weld tubes of various shapes.

- Solutions : Seamless integration of the laser welding process through a highly customized automation control system. The system has been successfully used in the rail transportation sector, e.g. for the manufacture of components such as crash beams, bumpers and exhaust pipes.

High precision control

- Difficulties : Realizing high-precision laser welding to ensure product quality and safety.

- Solutions : Equipped with high-precision sensors and advanced control algorithms, the system can achieve ±0.05mm precision control and ensure product quality in the manufacturing of key components in the field of rail transportation.

Railway transportation manufacturing

- Applications : The system has been successfully applied in the field of rail transportation for manufacturing components such as crash beams, bumpers, exhaust pipes, Compared with the traditional argon arc welding and high frequency welding, the system significantly improves product quality and production efficiency.

- Benefits : By adopting this system, the customer has not only improved product quality, but also significantly increased production efficiency and reduced production costs.

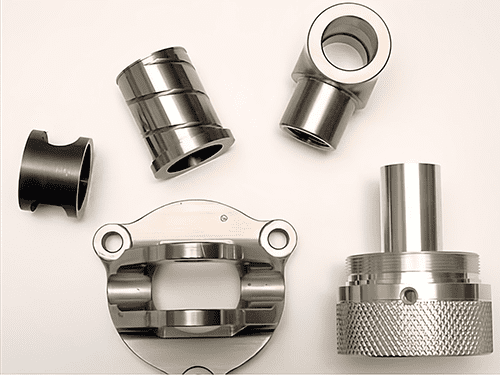

Automatic Welding Production Line for Automobile Transmission Parts

Automated production

- Difficulties : Realization of automated welding production lines for transmission components, improving production efficiency and product quality.

- Solutions : The system is equipped with fully automated loading and unloading manipulators, fully automated workpiece pressesfitting mechanism, laser cleaning mechanism, weld seam cleaning mechanism, etc., which realizes efficient automated production.

High quality welding

- Difficulties : Ensuring the quality of the weld and meeting the requirements for strength, weight and specific functions.

- Solutions : This system is equipped with a fiber optic welding head, seam tracking and laser inspection system for continuous production with low operating costs, high quality and high throughput.

Manufacture of vehicle transmission components

- Applications : The system is used for the welding assembly of vehicle transmission components, including main gear shaft components, clutch gear components, teeth of gear shafts, center teeth of gear shafts, and double gear assemblies.

- Benefits : By adopting this system, the customer realizes automated and efficient production, reduces operating costs, and improves product quality and yield.

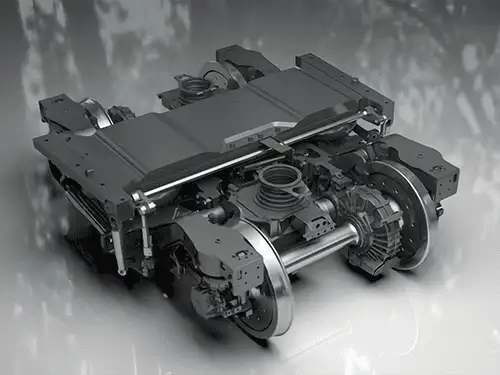

Cube Series-High Power Laser Deep Fusion Welding

High Power Deep Fusion Laser Welding

- Difficulties : Realizing high power laser deep fusion welding, ensuring welding quality and efficiency.

- Solutions : The Cube Series is a system designed for high power laser deep fusion welding with a high degree of precision and adjustable rotary axes to accommodate different operational requirements.

Efficient production processes

- Difficulties : Increase productivity, reduce errors, and ensure product consistency.

- Solutions : The system is equipped with a modern CCD vision system to ensure precise and consistent operation. Fiber lengths of up to 10 meters can be customized to meet diverse welding needs.

Manufacture of complex components

- Applications: The Cube Series is widely used in the manufacture of complex components, such as key parts in the field of rail transportation. Its high-power laser welding technology guarantees quality and reliability.

- Benefits : By adopting this system, the customer has improved productivity, reduced operational errors, ensured product consistency, and lowered operating costs.

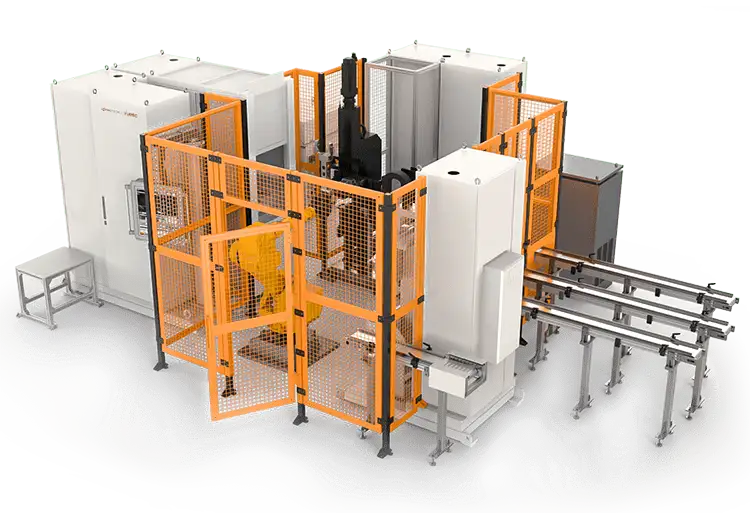

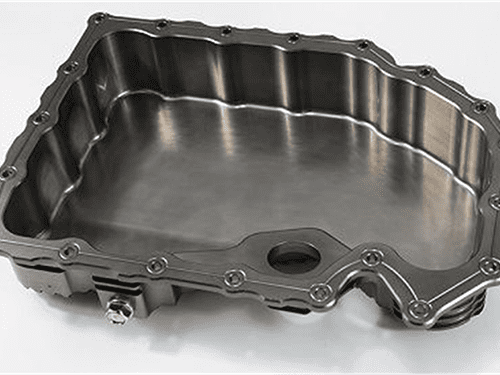

Multi-Robot Collaborative Intelligent Cleaning System

Complex internal cavity cleaning

- Difficulties : Realizing high-pressure cleaning of complex internal cavities to meet international cleaning standards.

- Solutions : This system utilizes multiple high payload 6-axis industrial robots to clamp workpieces and achieve precision cleaning of parts through high pressure, spot cleaning, rinsing and vacuum drying steps to meet ISO 16232 cleaning standards.

Efficient high-pressure cleaning

- Difficulties : Achieving efficient high-pressure cleaning and ensuring cleaning quality.

- Solutions : Adopting screw vacuum pump, high vacuum, energy saving and easy maintenance. Meanwhile, it is equipped with high resolution CCD camera, which can realize the compatible cleaning of many kinds of workpieces.

Internal cavity cleaning

- Applications : The system is used for internal cavity cleaning in the rail transportation sector to ensure that the cleanliness of train components meets standards.

- Benefits : By adopting this system, the customer has realized efficient internal cavity cleaning that meets international cleaning standards and improves the reliability of train components.

Lifting Walk-Behind Autocleaning System

Elevated transportation

- Difficulties : Realizing step-by-step lifting and transportation, ensuring smooth operation and high-precision positioning.

- Solutions : The system internally uses hydraulic cylinders or reducers to achieve step-by-step lifting and transportation, providing smooth operation and high-precision positioning.

Elevated transportation

- Applications : The system is used in the field of rail transportation to realize step-by-step lifting transportation and ensure the positioning accuracy of train components.

- Benefits : By adopting this system, the customer has improved the accuracy and reliability of operations and ensured the high-precision positioning of train components.

Pallet Walk-Through Cleaning System

Pallet conveyor

- Difficulties : Fixed-point cleaning, fixed-point blow-drying and vacuum drying by means of chain plus pallet transfer.

- Solutions : The system adopts chain plus pallet transfer to realize fixed-point cleaning, fixed-point blow-drying and vacuum drying of summer parts, making full use of space and reducing costs.

Parts Cleaning

- Applications : The system is used in the rail transportation sector for fixed-point cleaning, fixed-point blow-drying and vacuum drying of summer components to ensure the cleanliness of train components.

- Benefits : The customer has reduced costs, improved cleaning results and ensured the reliability of train components by utilizing this system.

Robotic Conveyorized Cleaning System

Automated cleaning

- Difficulties : Automatic loading, cleaning, blow-drying, unloading and pallet stacking.

- Solutions : This system uses single or multiple XYZ coordinate system manipulators to automate loading, cleaning, blow-drying, unloading, and pallet stacking for increased productivity.

Automated cleaning

- Applications : This system is used in the rail transportation sector to automate loading, cleaning, blow-drying, unloading and pallet stacking to ensure that train components are clean and ready.

- Benefits : By adopting this system, the customer has automated cleaning, increased productivity and reduced manual intervention.

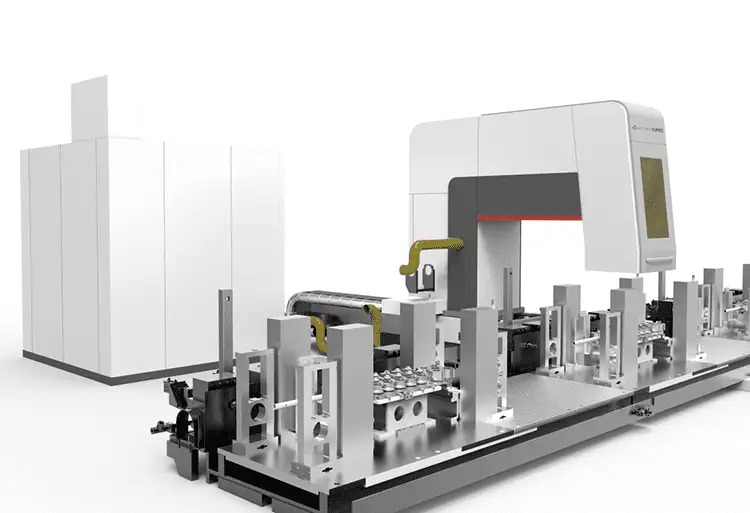

CNC Machine Tool Laser Welding System (JKA Series)

Integrated Controls & Air Handling

- Difficulties : Realization of integrated electrical control and air handling systems, space-saving for low-cost, high-quality laser processing applications for small and medium-sized parts.

- Solutions : The JKA series utilizes an integrated electrical control and air handling system, which saves space and ensures a small machine footprint. This is an ideal solution for applications that require low-cost, high-quality laser processing on small and medium-sized parts.

Multi-axis construction

- Difficulties : Realize multi-axis or four-axis linkage to adapt to different operation requirements.

- Solutions : The mainframe of the system adopts the gantry three-axis structure, which can realize three-axis or four-axis linkage. Depending on the requirements, the cutting head and welding head can be quickly switched. Accordingly, a quick-change interface is designed on the rotary table to change different fixtures at any time for subsequent expansion. This dual-purpose machine significantly reduces production costs and shortens production times.

Manufacture of small and medium-sized components

- Applications : The CNC Machine Tool Laser Welding System (JKA Series) is widely used in the production of small and medium-sized parts, and can be quickly switched between different fixtures to suit different operational needs.

- Benefits : The customer has been able to reduce production costs and shorten production times while ensuring high quality laser processing for a wide range of small and medium-sized parts.

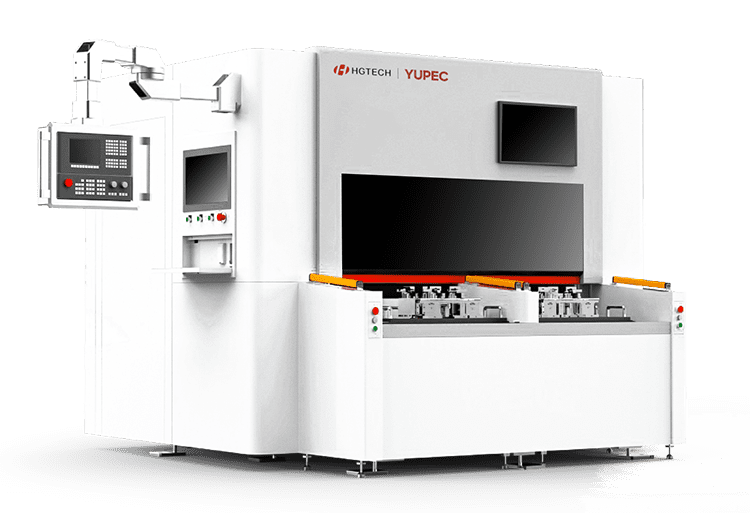

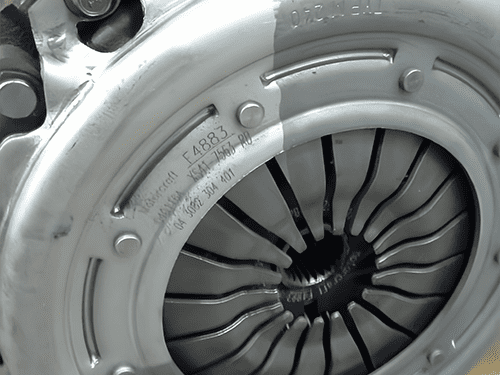

CNC Machine Tool Laser Welding System (JKB Series)

Large parts

- Difficulties : To realize laser welding of large parts, improve production efficiency and reduce the cost of individual products.

- Solutions : The JKB series of CNC laser welding stations are designed for mass production, increasing efficiency and reducing individual product costs. For welding large and medium-sized parts, the length and width of the slide can be expanded to meet job requirements. The system utilizes an integrated electrical control, operator station and air handling system to save shop floor space. In addition, a high degree of integrity saves installation time and provides easy and quick secondary installation for future expansion.

- Responses : The mainframe of the system adopts the gantry-type three-axis modular structure, which works with Siemens CNC system and can realize three-axis linkage control. According to the demand, the cutting head and welding head can be switched quickly. Accordingly, an interface for quick fixture change is designed on the slide table for subsequent expansion. This dual-purpose machine significantly reduces production costs and shortens production time. The maximum running speed of the mainframe is up to 30m/min, with a positioning accuracy of 05mm and a repeatability of 0.03mm. In addition, the mainframe has an XYZ axis travel of 1500mmx500mmx300mm, which can meet the machining needs of most medium and large parts.

Manufacture of large components

- Applications : The CNC Machine Tool Laser Welding System (JKB Series) is widely used in the manufacture of large parts, where different fixtures can be quickly switched to suit different operational needs. These parts include train doors.

- Benefits : By adopting this system, the customer has been able to reduce production costs and shorten production times, while at the same time guaranteeing high-quality laser processing for the manufacture of large parts.

Why choose us?

- Together with you, let’s promote the technological innovation of the industry together:

We can cooperate with major railroad equipment manufacturers to jointly develop more advanced and efficient production lines, and realize the intelligence and automation of railroad transportation equipment.

- Promote environmental protection and safety:

Through our advanced technology, we can help railroad equipment manufacturers achieve a greener and safer production process that meets the industry’s current high standards for environmental protection and safety.

- Long-term value and benefits of cooperation:

We can provide long-term technical support and services to the rail transportation manufacturing industry, helping you to meet the industry’s technical difficulties and challenges, and achieve more efficient and green production.