Fine Material Industry

Precision materials processing and manufacturing characteristics and technical difficulties:

- Manufacturing Features

From the perspective of consumers and end-users, precision material processing now presents a high degree of specialization and personalization. Consumers are demanding higher quality, especially in terms of precision and craftsmanship. In addition, consumers are more inclined to choose products with sustainable production practices and environmentally friendly features. As technology continues to evolve, the demand for precision material processing equipment continues to grow.

- Technical specifications and technical difficulties

From a manufacturer’s or producer’s point of view, meeting the high standards demanded by consumers or end-users is a technical challenge. Currently, the market is facing the double pressure of speed and precision. To ensure productivity and product quality, companies need to invest more resources in technology development and innovation. With the development of the agricultural machinery market, manufacturers will also encounter a series of new technical hurdles, including how to achieve a higher degree of automation and intelligent management, as well as how to ensure product stability and reliability.

Applications of YUPEC products in precision material processing:

Precision Fiber Laser Cutting Machine

In the field of LED technology, the LCF0120 can be used to manufacture extremely fine LED screen and luminaire components. Its minimum line width of 50μm ensures high-precision cutting for more efficient luminaire assemblies and more attractive designs.

In the field of precision machinery manufacturing, the LCF0120 can provide high precision and high efficiency cutting services for a variety of precision parts. Whether it is gears, springs or other complex parts, it ensures accurate and fast production.

In the field of semiconductor control equipment, the LCF0120 can provide high-precision and high-efficiency wafer and circuit board cutting services. Its high-precision and fast dicing functions ensure zero loss and zero error, resulting in increased throughput and efficiency.

This product laser precision cutting machine brings multiple benefits to its customers. First and foremost, it sets new standards of cutting precision across industries by harnessing the full potential of fiber laser technology, completely redefining throughput and efficiency and making it an indispensable piece of equipment in the modern industrial landscape.

Second, intelligent software algorithms not only implement graph nesting and corner smoothing functions, but also optimize workflow and improve production management.

In addition, the twin-screw and motor system ensures high cutting speeds of up to 1,000 mm/s without sacrificing quality, delivering unprecedented stability and precision in compliance with stringent quality standards, thus ensuring long-term, sustainable production practices.

Overall, the LCF0120 provides customers with an efficient, accurate and sustainable production solution.

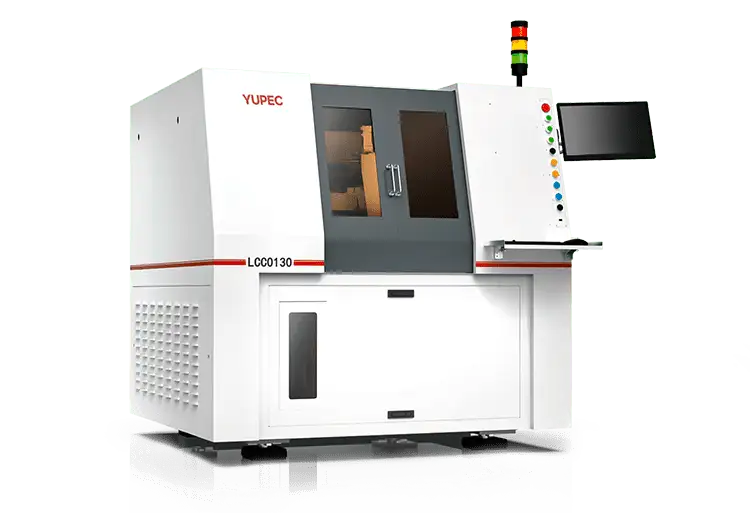

Precision CO2 Laser Cutting Machine

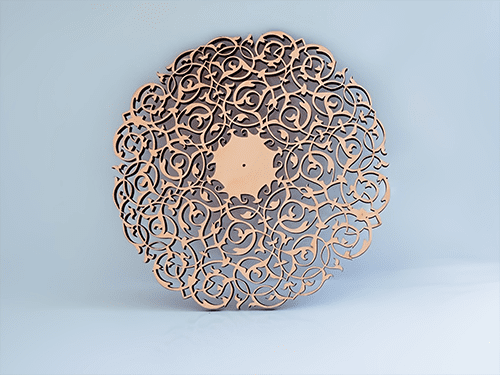

In the textile manufacturing field, the LCC0130 is able to provide high-precision and high-volume cutting. For example, when producing high-end apparel or furniture items, complex pattern and design cutting can be realized, ensuring high efficiency and quality output of the production line.

In the field of acrylic processing, the LCC0130 can quickly and accurately cut acrylic pieces of all shapes and sizes. Whether it is used to make signs, displays or other decorative items, it ensures a high degree of accuracy and consistency.

In the field of professional film processing, the LCC0130 can be used to cut a variety of professional film materials, such as filters and protective films. Its high degree of accuracy and repetitive positioning precision ensures meticulous and precise cutting, thus improving product quality and performance.

The LCC0130 CO2 laser cutting machine offers significant benefits to its customers, especially in the processing of non-metallic soft materials. Firstly, it offers excellent accuracy and stability, thanks to the solid construction of the whole machine casting, paving the way for high quality production. Secondly, it is equipped with professional laser cutting software with built-in graphic layout and sharp corner smoothing functions, which not only improves output quality but also simplifies the production management process.

In addition, the machine’s high efficiency is one of its distinguishing features. the twin-screw, twin-motor drive system significantly improves productivity, with operating speeds of up to 1,000 mm/s. Together with excellent xy-axis positioning accuracy and repeatability, it ensures detailed and meticulous cutting, which is particularly important when working with materials such as textiles, acrylic and specialty films. To summarize, the LCC0130 is the efficient, high-precision solution you can rely on to cut non-metallic materials, dramatically improving the quality and efficiency of your production line.

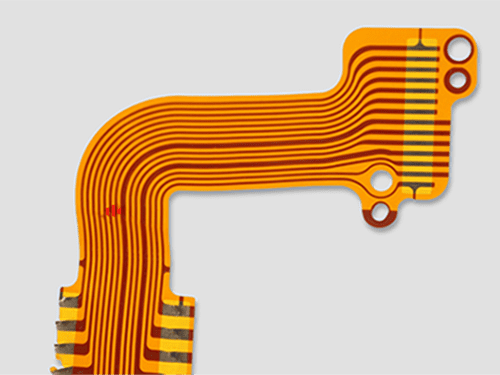

Precision UV Laser Cutting Machine

In the leather processing field, the LCU0201 can provide fine and efficient leather cutting solutions for the leather goods and fashion industries. For example, in the production of high-end leather bags or shoes, fine pattern and design cutting can be realized without having to worry about burnt or broken edges that may be caused by traditional cutting methods.

In the field of thin film material processing, the LCU0201 can efficiently cut a variety of complex and fine shapes. Its UV laser technology ensures smooth, heat-affected-free cutting seams, which are key to manufacturing high-quality protective films for displays and other electronic product film materials.

In the field of carbon paper processing, the LCU0201 can be used for high-precision cutting of carbon paper for use in the manufacture of specific crafts or office supplies. Its high efficiency and fine cutting ability ensures the quality and consistency of the final product.

The LCU0201 UV laser cutting machine is a transformative soft material processing solution. Firstly, its in-house software development capabilities provide customers with powerful editing functions that streamline the production management process and provide multi-level privilege operation functions. Secondly, the machine utilizes a high-speed and efficient linear motor to ensure high speed and high efficiency.

What’s more, its “one-piece separation” style offers the unique ability to string and separate materials for easier material handling. At the same time, UV technology ensures smooth, thermally efficient cuts that minimize thermal impact, resulting in higher quality products. Finally, the machine is environmentally friendly and economical, with integrated energy-saving components that reduce running costs without compromising performance.

The LCU0201 UV laser cutter provides customers with an unmatched solution for processing soft materials at high speeds, efficiencies and quality, making it the preferred choice for industries that require the highest level of detail and precision.

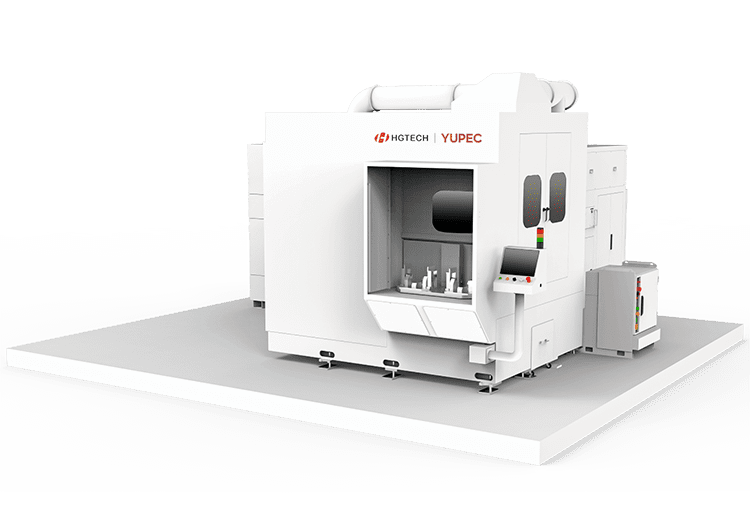

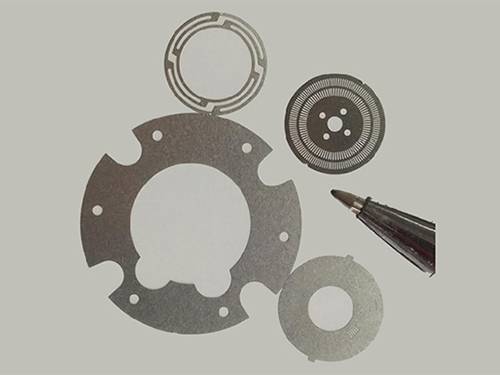

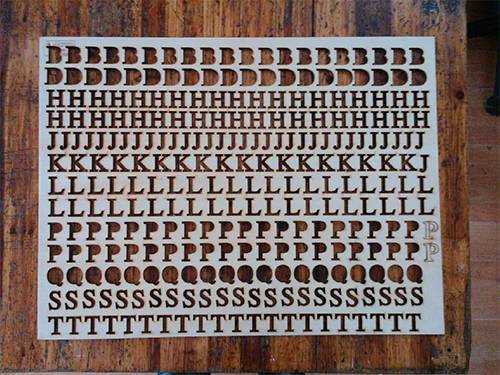

Apex Series-Laser Micromachining

In the manufacture of smartphone cameras, the Apex series can be used for high-precision optical glass cutting, ensuring that clarity and image quality are significantly improved to meet consumer demand for high-quality cameras.

In the jewelry industry, the Apex series can be used for fine metal micro-perforation cutting and drilling, resulting in intricate and fine jewelry designs, making the product more attractive and valuable to the market.

In the electronics industry, especially in high-frequency PCB manufacturing, Apex series can realize precision cutting and micro-hole machining, which ensures the high quality and performance of the products, in line with the high standard and complex needs of modern electronic products

With the Apex Series, customers can enjoy the multiple benefits of advanced technology, high machining accuracy and increased efficiency. This advanced laser micromachining technology allows for faster production cycle times while maintaining high product quality and precision, resulting in reduced scrap rates and production costs.

What’s more, it can provide higher flexibility and customization options to meet customers’ specific needs and high standards. In addition, by reducing production time and increasing productivity, customers can respond faster to market demands and seize more business opportunities, resulting in higher profitability and market share.

Axis Series Precision Cutting

In the automotive industry, the Axis series can be used for precision cutting of automotive components, such as engine parts and key precision structures in the body and interior of the car, to ensure the quality and safety of the products and to meet the high standards and strict requirements of the automotive industry.

In the aerospace industry, the Axis series can be used for precision cutting of high-strength materials and alloys, providing a highly accurate and reliable cutting solution for aerospace parts, ensuring product durability and performance.

In the construction industry, the Axis series can be used for high-precision cutting of steel and other metal structures, achieving faster project cycle times and greater structural safety, meeting the high standards and demands of the modern construction industry.

By using the Axis series, customers can realize higher productivity and product quality, thus significantly increasing their competitiveness in the market. This series offers best-in-class precision cutting solutions that can significantly reduce production time and costs while ensuring high product quality and accuracy. In addition, it is available in a wide range of table sizes and laser power options, thus providing greater flexibility and customization to meet the specific needs of different customers. Customers can also realize faster time-to-market and seize more market opportunities by using the Axis Series, resulting in higher profitability and market share. Overall, the Axis series can provide customers with an efficient, reliable and cost-effective laser cutting solution that is ideal for the modern manufacturing industry.

Non-Metal Flexible Laser Cutting System

Automotive Airbag Manufacturing Field. With the high-precision X/Y staggered axes and powerful CO2 laser source, the system is able to accurately and efficiently cut the mounting holes for airbags on automotive instrument panels, realizing highly efficient, precise, and stable machining, which enhances the safety and quality of the automobiles.

Automotive Interior Material Processing, the system can perform fine cutting and engraving on all kinds of non-metallic materials such as leather, fabric, etc. Through the flexible processing system and multi-functional and humanized HMI interface, it realizes the efficient, high-quality and high-precision processing of interior materials.

Ultrasonic welding of automotive parts, the system can be equipped with optional ultrasonic welding function, which can realize the welding of various brackets, not only improve the welding efficiency, but also ensure the welding quality and stability through the PLC control system, thus enhancing the structural stability and service life of the product.

The choice of non-metallic flexible laser cutting system not only marks the process innovation and product quality improvement, but also a comprehensive optimization of the enterprise production efficiency and economic benefits.

First, its integrated multifunctional machines dramatically reduce operating costs, while significantly reducing the learning curve for employees and increasing productivity by simplifying the operator interface.

Secondly, the system opens up new innovation opportunities for automotive manufacturers through high-precision cutting and optional ultrasonic welding capabilities that promote improved product quality and safety.

Finally, its flexible power options to meet diversified project needs bring the automotive manufacturing industry the dual benefits of efficiency and innovation, thus solidifying the company’s leadership and competitive advantage in the marketplace.

With this efficient laser cutting system, you can not only improve the quality and safety of your products, but also enhance your company’s market reputation and customer satisfaction, winning more market share and profit margins for your company.

YUPEC products have set the industry benchmark in precision materials processing and manufacturing through continuous technological innovation and optimization. They not only boast outstanding precision and efficiency, but also offer a wide range of environmentally friendly and sustainable production solutions. In terms of industry outlook, YUPEC is expected to become a leading company in this field as the market continues to demand precision and efficient equipment.

By choosing YUPEC as a partner, companies can enjoy a range of long-term benefits and value. First, YUPEC’s products provide efficient and sophisticated solutions that help improve production efficiency and product quality. Second, by partnering with YUPEC, companies have access to best-in-class technical support and services that enable greater production automation and intelligence. Finally, YUPEC also focuses on environmental protection and sustainable development, which can help companies realize green production and long-term development.