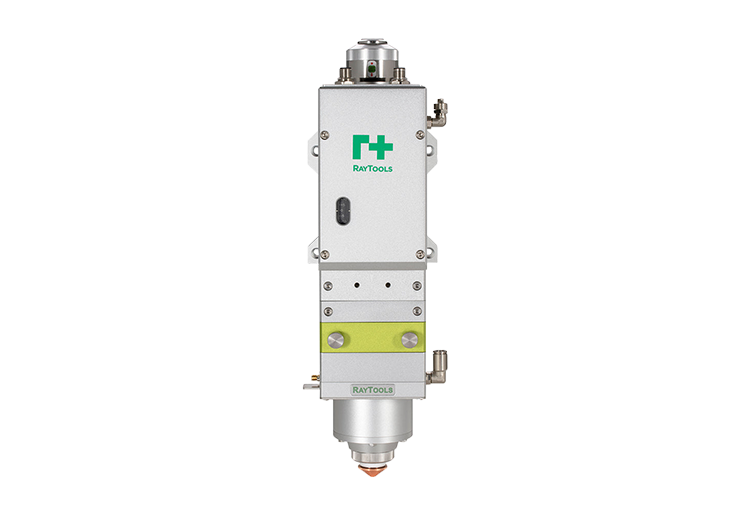

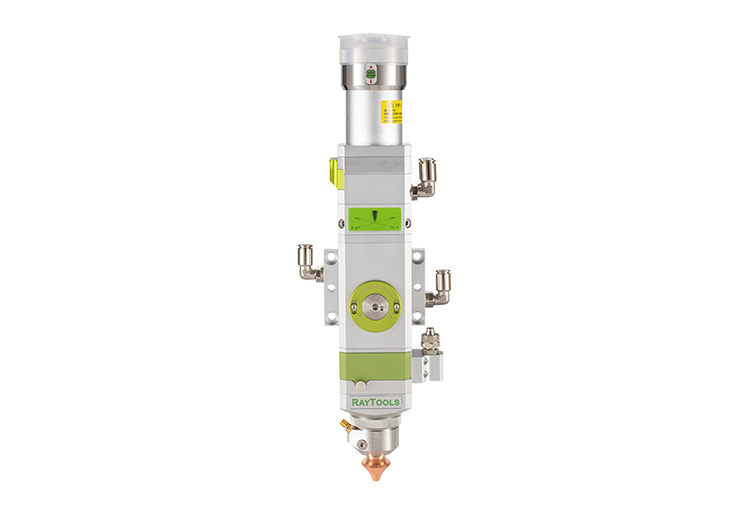

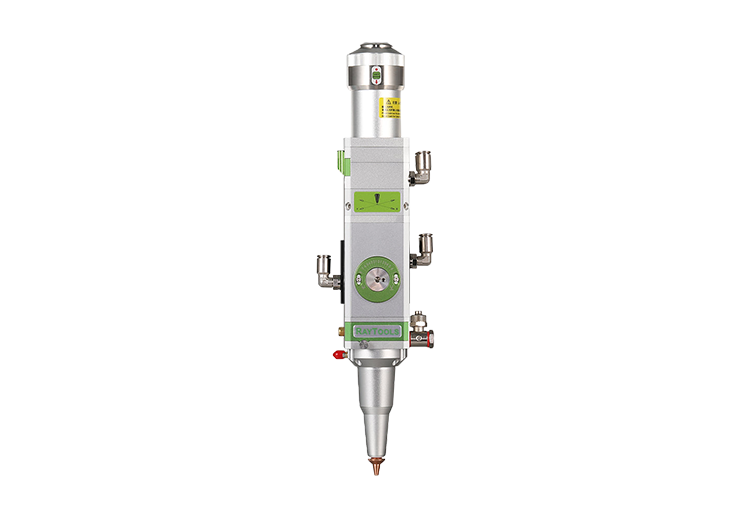

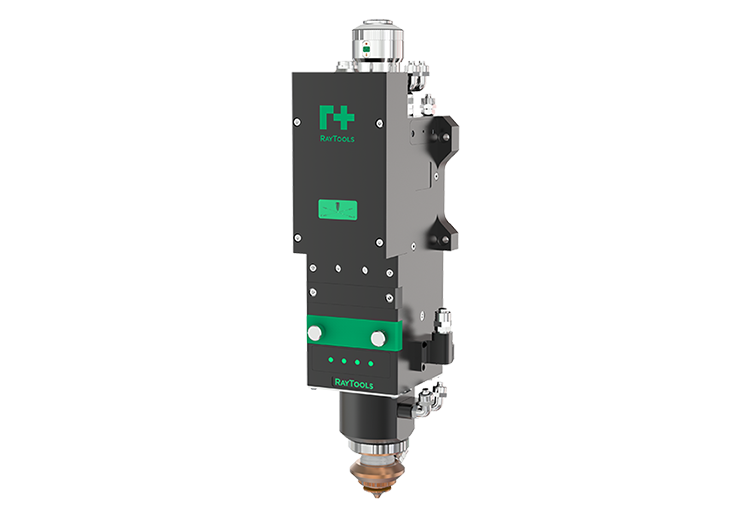

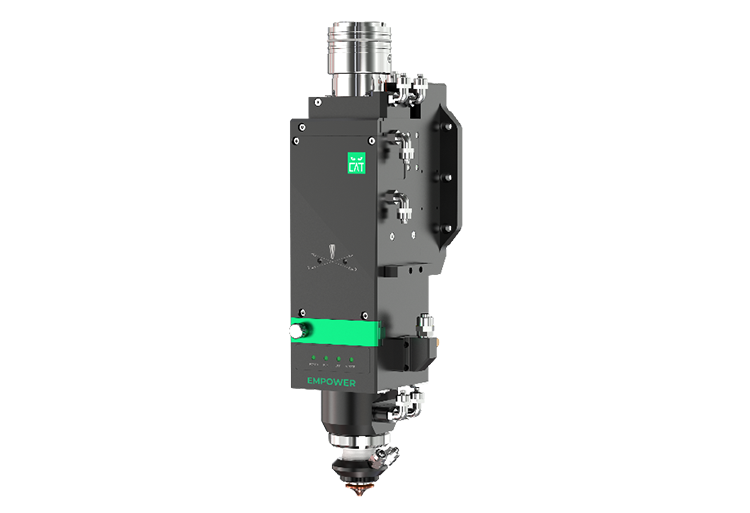

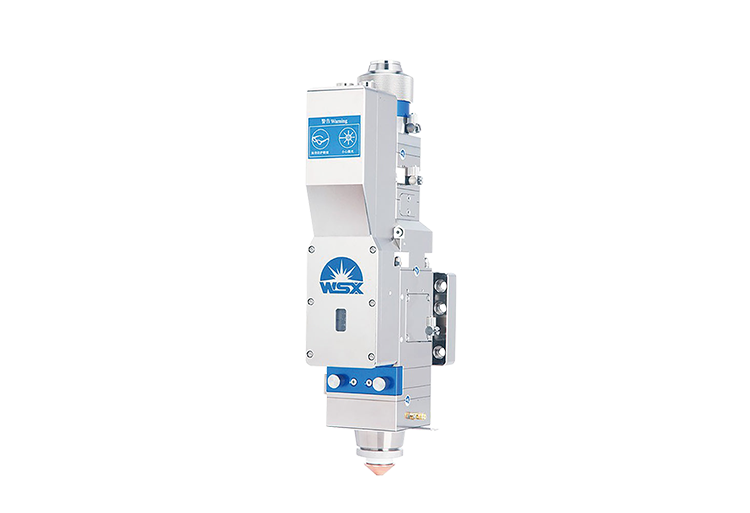

The Fiber Laser Cutting Head plays a pivotal role in the performance and capabilities of laser cutting systems, allowing for precise, fast, and versatile cutting of various materials including metals, plastics, and composites. Its design and functionality directly impact the quality, speed, and efficiency of the laser cutting process, making it a critical component in industrial manufacturing and fabrication processes.

Main Components of Fiber Laser Cutting Heads

The Fiber Laser Cutting Head comprises essential components such as the collimating and focusing lens, QBH connector, protective windows, locking ring, nozzle connector, laser ceramics, and laser nozzles. Together, these elements ensure precise laser beam delivery, optimal energy concentration, protection against debris, stable positioning, and efficient gas delivery, contributing to the overall effectiveness and reliability of laser cutting operations.

Expand to learn more

- Collimating & Focusing Lens : The collimating and focusing lens is a critical component of the Fiber Laser Cutting Head, responsible for converging the laser beam to a precise focal point on the workpiece. It ensures optimal energy concentration for efficient and accurate cutting operations.

- QBH Connector : The QBH connector serves as the interface between the fiber optic cable and the cutting head. It enables the delivery of the laser beam from the fiber optic cable to the cutting head while maintaining alignment and minimizing energy loss.

- Protective Windows : Protective windows are transparent covers that shield the lens and other sensitive components of the cutting head from debris, splatter, and other contaminants generated during the cutting process. They help maintain optical clarity and protect the integrity of the cutting head.

- Locking Ring : The locking ring secures the components of the cutting head in place, ensuring stable and precise positioning during operation. It prevents vibration or movement that could compromise the accuracy and effectiveness of the cutting process.

- Nozzle Connector : The nozzle connector attaches the cutting head to the nozzle, which directs assist gases onto the workpiece to enhance cutting efficiency and quality. It provides a secure connection while allowing for easy removal and replacement of the nozzle as needed.

- Laser Ceramics : Laser ceramics are often used in the construction of the cutting head due to their high temperature resistance and durability. They provide thermal insulation and structural support for the nozzle and other components, helping to maintain stable operating conditions and prolonging the lifespan of the cutting head.

- Laser Nozzles : The nozzle is a critical component of the cutting head responsible for delivering assist gases, such as oxygen or nitrogen, to the cutting zone. It helps remove molten material and debris from the cutting path, improving cutting quality and preventing material buildup on the workpiece.

Send us a message

Don’t hesitate to ask, we usually reply in 24 hours or less!

Contact Information

Yupec Laser Germany GmbH

Itterpark 2, 40724 Hilden, Germany

- +49 2103 9674 492 / +49 2103 9676 682

Company Details

Yupec Laser Germany GmbH

Amtsgericht Jena, HRB 519333

Ust-Id~Nr. DE3552294798