Agricultural Machinery Industry

Manufacturing Characteristics and Technical Challenges in the Agricultural Machinery Industry

- Manufacturing Characteristics : From the perspective of consumers and end-users, the agricultural machinery industry is evolving towards intelligence and automation. Consumers and customers are more inclined to choose products characterized by high efficiency, time-saving, and environmental protection. The pursuit of multifunctionality and intelligent control systems is also a current market trend. In addition, technologies capable of increasing yield and quality are highly welcomed.

- Technical Specifications and Challenges : For manufacturers, meeting the high standards and diversified demands of consumers and end-users is a technical challenge. Technical innovation and investment in research and development are the key focuses in the current and future agricultural machinery industry. As technology advances rapidly, maintaining technological leadership and product updates is a significant concern. Moreover, facing increasingly strict environmental and safety standards, ensuring the environmental friendliness and safety of products is a technical difficulty.

Application and Customer Benefits of YUPEC Company Products in the Agricultural Machinery Industry

Robot Flexible Laser Cutting and Welding System

Case 1 : Utilized in the agricultural machinery manufacturing to quickly and precisely cut various metal materials.

Case 2 : Employed for the automatic welding of agricultural machinery components, enhancing welding quality and efficiency.

Case 3 : Facilitates the customization and small-batch production of agricultural machinery.

Benefits : Clients can achieve efficient, accurate, and personalized agricultural machinery production using this system, thereby enhancing production efficiency and product quality while reducing manufacturing costs.

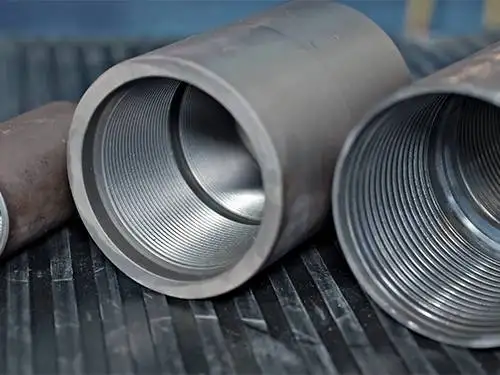

Line Pipe Laser Welding Connection System

Case 1 : Used in agricultural irrigation systems for pipe connections, offering more robust and durable connections through laser welding.

Case 2 : Utilized during the manufacture of agricultural machinery equipment for connecting structural components, ensuring the stability and safety of the equipment.

Case 3 : Employed in constructing agricultural greenhouses, offering quick and sturdy pipeline connection solutions.

Benefits : This system provides fast, efficient, and high-precision pipeline connections, helping reduce maintenance costs and extend equipment lifespan.

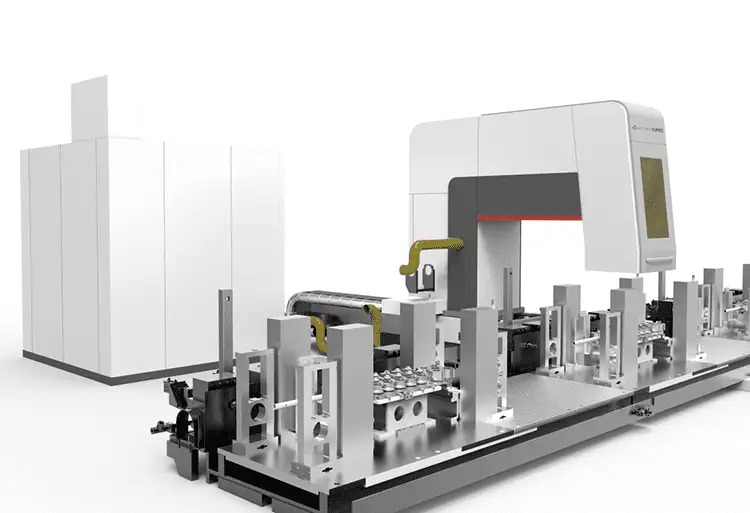

CNC Machine Tool Laser Welding System - JKA series

Case 1 : Used for the automatic welding of agricultural machinery parts, improving production efficiency and welding quality.

Case 2 : Employed for the repair and maintenance of agricultural tools and equipment, reducing maintenance costs and time.

Case 3 : Used in the production of customized agricultural machinery equipment, offering highly customized solutions.

Benefits : This series can enhance production efficiency and quality while reducing production costs, bringing higher investment returns to customers.

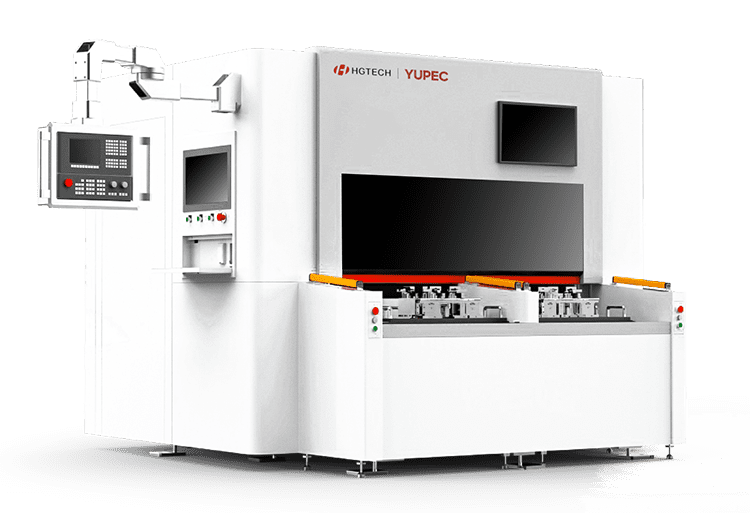

CNC Machine Tool Laser Welding System - JKB series

Case 1 : Applied for laser welding reinforcement treatment on wear-resistant parts of agricultural machinery, improving the wear resistance and lifespan of components.

Case 2 : Used for the rapid prototyping and small-batch production of agricultural machinery accessories, reducing production cycles and costs.

Case 3 : Facilitates precise welding in agricultural machinery maintenance, lowering maintenance costs and time.

Benefits : The JKB series can improve the efficiency and quality of agricultural machinery manufacturing and maintenance, bringing higher economic benefits and better user experience to customers.

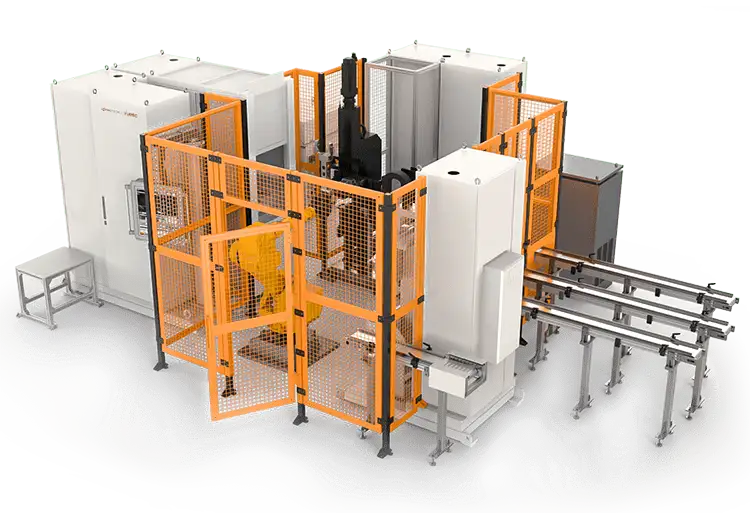

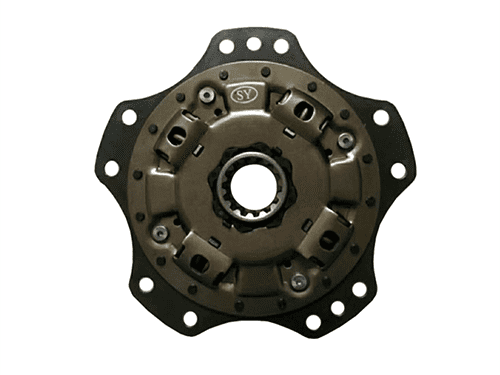

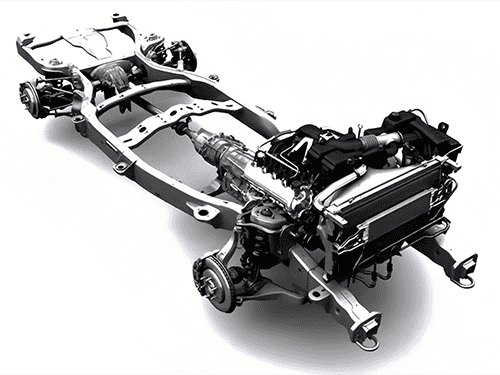

Automatic Welding Production Line for Automobile Transmission Parts

Case 1 : Used in the automatic welding production line for agricultural machinery transmission parts, greatly improving production efficiency and product quality.

Case 2 : Offers specialized welding solutions for transmission parts in agricultural machinery, ensuring the performance and reliability of products.

Case 3 : Realizes mass production of transmission parts for agricultural machinery, reducing production costs and cycles.

Benefits : This production line can provide customers with a one-stop welding solution, not only enhancing production efficiency but also ensuring the quality and performance of products, bringing higher profits to customers.

Cube Series-High Power Laser Deep Fusion Welding

Case 1 : Used for deep fusion welding of structural components in agricultural machinery equipment, ensuring the stability and safety of structures.

Case 2 : Applied in the strengthening and repair of agricultural machinery cultivation tools, prolonging the lifespan of the tools.

Case 3 : Utilized in the construction and maintenance of agricultural facilities such as greenhouses and warehouses, providing a fast and reliable welding solution.

Benefits : This series of products can offer efficient, stable, and deep laser welding solutions, meeting the high quality and efficiency welding needs of the agricultural machinery industry, creating higher value for customers.

Multi-Robot Collaborative Intelligent Cleaning System

Case 1 : Multi-robot collaboration for the cleaning and maintenance of agricultural equipment, ensuring long-term efficient operation of equipment.

Case 2 : Used in the cleaning and maintenance of large-scale farmlands, achieving efficient and environmentally friendly agricultural production.

Case 3 : Employed for the cleaning and maintenance of agricultural storage facilities, extending the lifespan of the facilities.

Benefits : This system can provide agricultural enterprises with an efficient and intelligent cleaning solution, reducing maintenance costs and improving agricultural production efficiency.

Smart Laser Handheld Welders

Case 1 : Used for the quick maintenance and processing of agricultural machinery equipment and tools, improving maintenance efficiency.

Case 2 : Offers on-site welding repair and installation services for agricultural facilities, saving time and cost.

Case 3 : Used for the rapid prototyping and custom production of agricultural machinery accessories, offering flexible and efficient solutions.

Benefits : The smart laser handheld welders can provide agricultural enterprises with quick, efficient, and flexible welding solutions, reducing maintenance costs and improving production efficiency.

Yupec products, with their advanced laser technology and automation solutions, have a significant technological advantage in the agricultural machinery industry. These products can help companies achieve efficient, precise, and eco-friendly production, meeting the market demands for intelligence and personalization. Looking forward to the future, with the advancement of agricultural modernization, Yupec’s products and solutions will have a broader market space and application prospects.

By cooperating with Yupec, companies can obtain advanced technical support and product solutions, helping them to achieve technological upgrades and industrial transformation. Meanwhile, Yupec can also provide comprehensive service support for companies, assisting them in optimizing production processes and management systems, enhancing their market competitiveness and profitability.