Table of Contents

In modern manufacturing, welding technology has always played a crucial role. In the field of welding, handheld laser welding has gradually emerged as an advanced technology. Its characteristics of high precision, minimal heat impact, and high efficiency make it excel in the field of thin plate welding, providing new solutions to a series of challenges in traditional welding methods.

Challenges in Traditional Thin Plate Welding

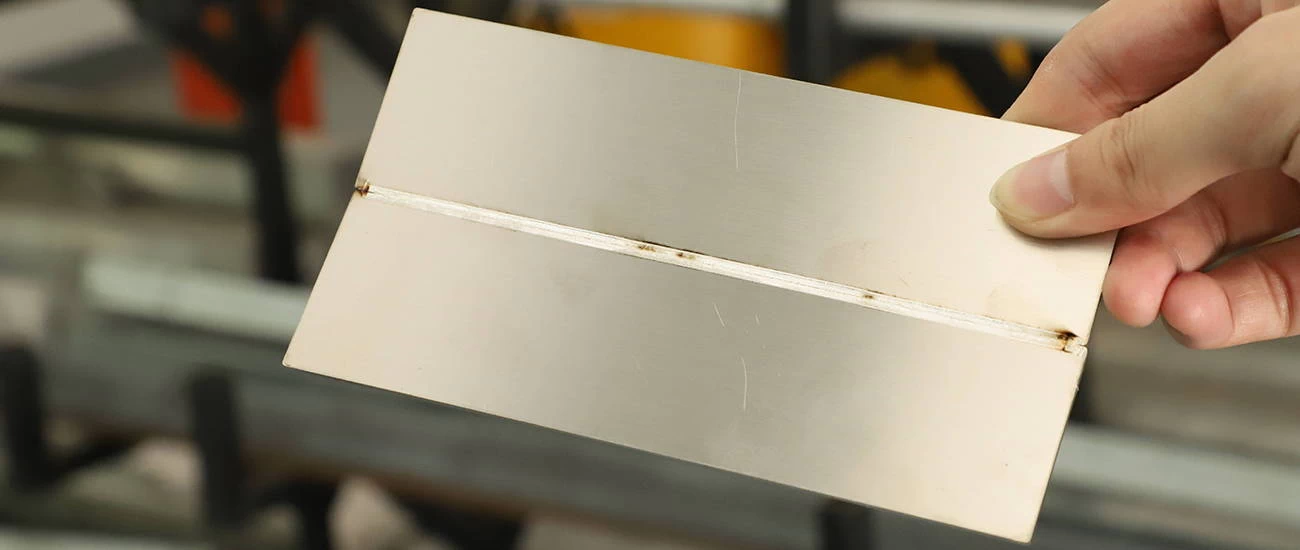

Common laser welding is considered thin plate welding when the thickness is in the range of 0.5mm to 4mm. For handheld welding of thin plates, we specifically refer to welding metal sheets of 0.5mm and below. According to promotional materials from handheld welding products on the market, the thinnest metal sheet size achieved is 0.3mm.

Thin plate welding, as a critical technology in manufacturing, faces a series of complex and challenging issues. These challenges not only directly affect the effectiveness of the welding process but also impact the quality and performance of the final product. Challenges in traditional thin plate welding include:

Deformation Issues:

Thin plates are prone to significant deformation due to local heating during the welding process, leading to noticeable shape changes after welding. The high thermal conductivity of thin plates results in uneven temperature distribution in the welding area, causing local contraction or expansion. This deformation may lead to instability in the geometry and dimensions of the workpiece after welding, posing a significant problem for applications with high dimensional accuracy requirements, such as electronic devices or automotive components.

Porosity and Weld Seam Quality:

Controlling the quality of pores and weld seams is a challenge when welding thin plates. Due to the thin nature of the plates, pores can easily form during the welding process, affecting the welding quality. The uniformity and robustness of the weld seam are crucial for ensuring the strength and durability of the welded joint, but achieving this on thin plates can be challenging.

Welding Parameter Control:

The significant heat generated by arc welding may be challenging to control precisely, leading to unstable heat input. This can cause excessive heating of thin plates, subjecting the weld seam area to unnecessary heat impact and increasing deformation and quality issues during the welding process.

Equipment Adaptability:

Traditional arc welding equipment is often bulky and challenging to adapt to some complex structures or hard-to-reach welding positions. This may not be flexible enough for some specific thin plate welding scenarios.

The key to addressing these challenges in thin plate welding lies in considering material characteristics, welding process parameters, equipment selection, and adopting suitable technological means and process optimization to minimize deformation, improve welding quality, and enhance efficiency.

Advantages of Handheld Laser Welding Machine in Thin Plate Welding

Small Heat-Affected Zone (HAZ):

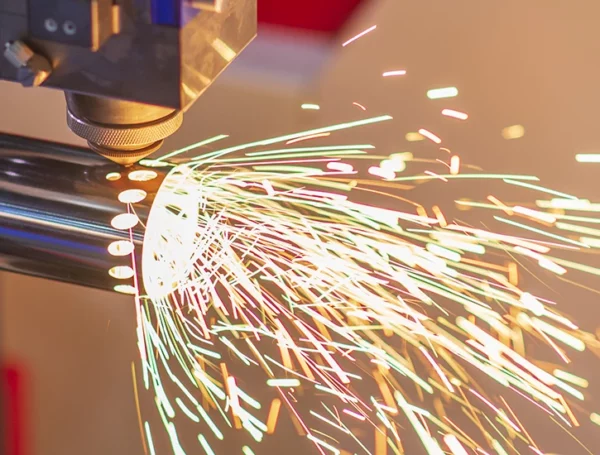

The laser beam from the handheld laser welding machine is highly concentrated, providing an extremely small heat-affected zone. Compared to traditional arc welding, it significantly reduces heating of the surrounding materials, thereby reducing the risk of thin plate deformation.

Precision Welding:

The high energy density and focusing capabilities of the laser beam enable the handheld laser welding machine to achieve highly precise welding. This is particularly crucial in thin plate welding, ensuring the accuracy and consistency of the welding process.

Rapid Cooling:

Due to the high energy density of laser welding, the heating and cooling processes in the weld seam area are very rapid. This helps reduce deformation and improves welding quality. In traditional welding methods, the larger heat-affected zone leads to slower cooling, potentially causing deformation and other undesirable results.

Non-Contact Welding:

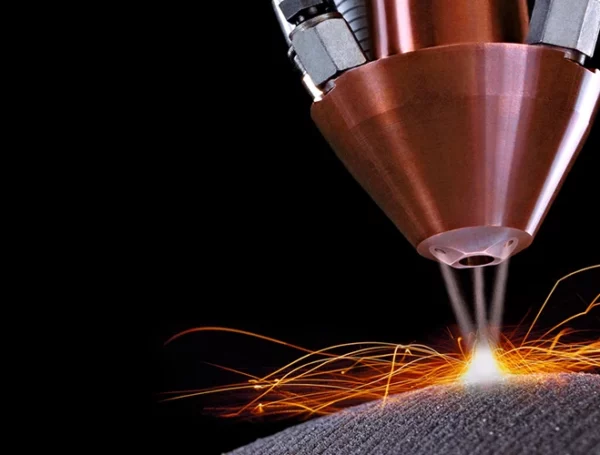

The handheld laser welding machine achieves non-contact welding, where the laser beam directly acts on the welding material without the need for physical contact. This is especially important for handling fragile materials like thin plates, avoiding surface damage or deformation caused by physical contact.

High Controllability:

The handheld laser welding machine is equipped with an advanced control system, allowing highly precise control of welding parameters. Adjustments to welding speed, power, focal length, and other parameters are more finely tuned, enabling operators to adapt to different welding requirements and improving welding stability and consistency.

Strong Adaptability:

The flexibility and maneuverability of the handheld laser welding machine make it suitable for complex thin plate welding scenarios. It can easily handle welding tasks in different angles, complex structures, and narrow spaces, providing greater convenience for operators.

In summary, compared to traditional arc welding, the handheld laser welding machine has more advantages in thin plate welding, particularly in precision, heat impact control, and adaptability. It has driven technological upgrades and quality improvement in the field of thin plate welding.

Applications of Handheld Laser Welding in Thin Plate Welding

Handheld laser welding exhibits excellent applicability in thin plate welding and can be used for various types of thin plate materials, including but not limited to stainless steel, aluminum alloy, titanium alloy, etc. This versatility has led to widespread applications in industries such as electronics, automotive, medical instruments, and more.

-

Electronics Industry:

In the electronic manufacturing sector, especially in the production of microelectronic devices, handheld laser welding is widely used for welding tiny electronic components and connecting thin plate circuits. The high precision and small heat-affected zone of the laser enable precise welding of microscopic structures, ensuring the reliability and performance of electronic devices.

-

Automotive Industry:

In automotive manufacturing, thin plate welding is a crucial step in the process of body manufacturing. Handheld laser welding machines can be used to weld automotive thin plate structures, including body shells and chassis components. Its high precision and rapid cooling characteristics contribute to ensuring the quality of weld joints, enhancing overall body strength, and achieving lightweight construction.

-

Aerospace Industry:

In the aerospace sector, handheld laser welding machines are extensively used in the assembly and repair of aircraft structures. Due to the high strength and lightweight nature of aerospace components, the high precision and small heat-affected zone of laser welding make it an ideal choice for handling these materials.

-

Medical Device Manufacturing:

Medical devices often require high precision and cleanliness. Handheld laser welding machines can be used for producing thin plate components of medical instruments, such as surgical tools and medical sensors. Its non-contact and highly controllable characteristics help ensure the cleanliness and quality of the welding site.

-

Battery Manufacturing:

In battery manufacturing, handheld laser welding machines are widely used for connecting battery cells and components. Efficient welding of thin plates allows batteries to achieve efficient energy conversion in compact spaces, improving the overall performance of the battery pack.

-

Stainless Steel Kitchenware Manufacturing:

In kitchenware manufacturing, the welding of thin stainless steel sheets requires high aesthetics and structural strength. Handheld laser welding machines can achieve high-quality welding, avoiding welding slag and pores that traditional methods may produce, enhancing the appearance and quality of kitchenware.

YUPEC Handheld Laser Welding Machine Series

The HW series handheld laser welding machine is a new generation laser welding product with an integrated design. It features an aesthetic appearance, stable performance, easy installation, and simple operation, ensuring high safety. It is characterized by fast welding speed, high efficiency, good welding effects, minimal consumables, long lifespan, and environmental friendliness. It can be widely used in the welding of kitchen utensils, doors and windows, railings, stairs and elevators, stainless steel furniture, hardware sheet metal, billboards, craft gifts, automotive repair, automotive manufacturing, rail transportation, and other industries.

The air-cooled laser welding machine features a second-generation fiber optic transmission system with better and more stable beam quality and no consumables required. In comparison to water-cooled welding machines that often face freezing issues, Smart-HWA exhibits clear advantages in cold regions. The dual-fan design provides strong heat dissipation capabilities, reducing energy consumption. Air-cooled fiber laser welding machines are used for welding metal sheets of carbon steel, stainless steel, aluminum, copper, and other materials.

This advanced equipment stands out for its compact design, occupying only half the space of traditional laser welding machines. The small size not only improves operational convenience but also significantly reduces transportation costs. The SMART HWS series combines all the features of traditional water-cooled handheld laser welding machines and achieves a notable 30% efficiency improvement through an upgraded control system. Choosing the SMART HWS series allows for more intelligent and efficient metal welding.

The SMART HWE 3-in-1 multifunctional handheld fiber laser welding machine comes in power options of 1kW, 1.5kW, 2kW, and 3kW, standing out for its efficiency and adaptability. It can meet various requirements, including metal cutting, welding, rust removal, and surface cleaning. The machine is particularly effective for robust welding tasks. It features ergonomic design, is lightweight and compact, ensuring optimal productivity.

In addition, Yupec Laser is committed to addressing customer challenges in thin plate welding applications and can provide customized solutions:

Welding Power:

Stability of welding power is crucial when welding plate thicknesses below 0.5mm. The stability of handheld welding power significantly affects weld seam quality and plate melting. Yupec Laser achieves high-stability power output through integrated design, self-developed dual-circuit refrigerant direct cooling system, and power adaptive restoration technology.

Welding Process Package:

Handheld welding products often require repeated tuning of process packages in actual customer applications, in addition to the mentioned “power instability” affecting weld quality and plate melting. More commonly, this is due to handheld welding directly adopting existing market process package parameters without validation testing based on actual customer application scenarios and without adaptation to the handheld welding product itself. Yupec Laser, through both product development and welding process, has fine-tuned and improved process package parameters multiple times. It further upgraded the control program of this series of products, meeting industrialization demands for thin plate welding.

Wire Feeder:

Thin plate welding relies heavily on welding speed. However, self-melting welding cannot precisely control welding speed. Relying solely on the feel of hand welding operations, variations in speed can easily lead to melting. Thus, thin plates cannot be separated from wire feeders for welding. The thinner the plate, the higher the requirements for wire feeding speed and accuracy. At this point, the wire feeder, as a core auxiliary tool for welding, needs to match the main machine’s performance. The Yupec series handheld welding, paired with self-developed wire feeders, embedded with self-developed intelligent process package matching the main machine performance, fully embodies the advantages of integration—cooperation, suitability, and fitting. There is no need for repeated tuning of main machine and wire feeder parameters, providing a more relaxed and efficient user experience.

Conclusion

In conclusion, handheld laser welding technology has shown remarkable performance and widespread application prospects in the field of thin plate welding. As manufacturing industries continue to evolve, the advantages of handheld laser welding machines will drive continuous upgrades in thin plate welding technology, providing robust support for innovation and quality improvement in manufacturing processes. The YUPEC Laser series of products have played a positive role in innovation and practical applications in this field, providing users with efficient and precise welding solutions.