Table of Contents

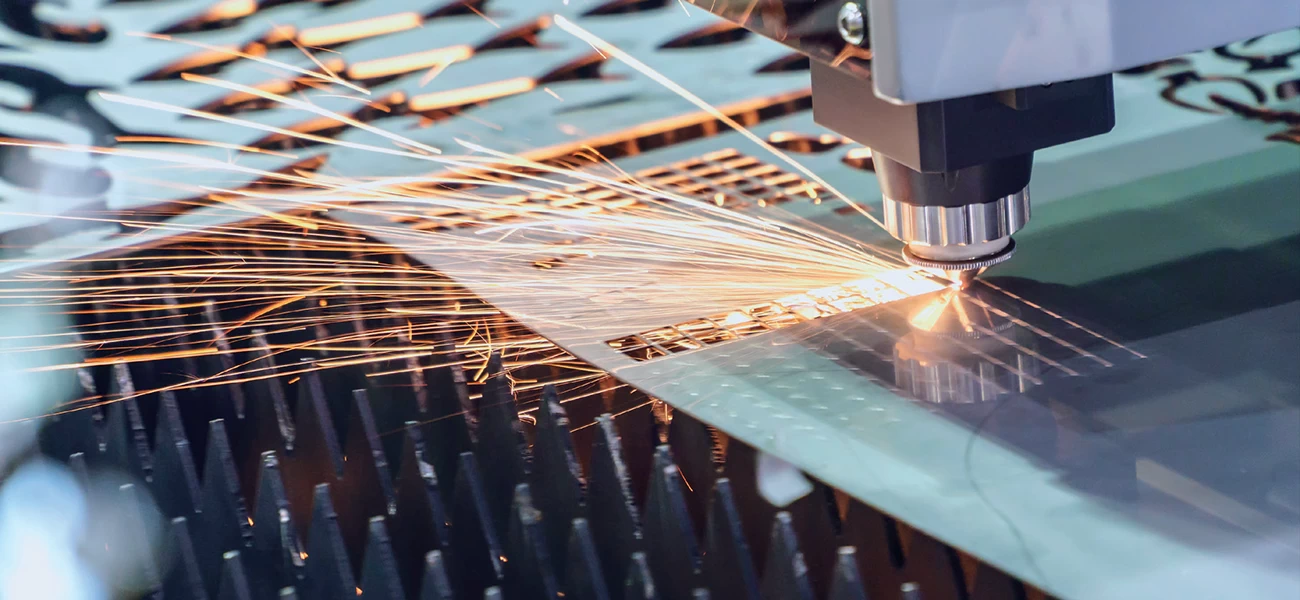

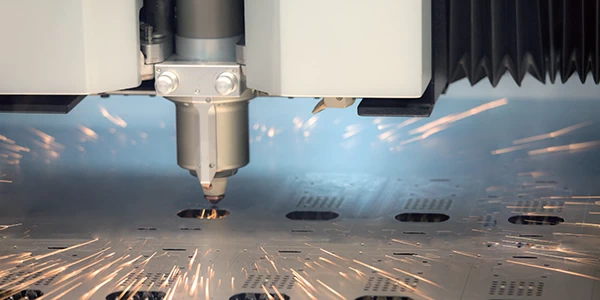

In modern manufacturing, improving efficiency is a core goal for enterprises. Laser cutting technology, with its high precision, high speed, and high flexibility, has become an essential tool for enhancing efficiency. This article will explore in depth how laser cutting technology boosts manufacturing efficiency and its profound impact on the industry.

High Precision Leads to Low Error Rates

Laser cutting technology is renowned for its exceptional precision. Compared to traditional mechanical cutting methods, laser cutting can achieve micron-level accuracy. This high precision not only reduces material waste but also ensures the consistency of component dimensions, thereby lowering rework and maintenance costs.

For example, in the aerospace and automotive industries, components require extremely high precision. The application of laser cutting technology has significantly improved production efficiency and product quality in these sectors. In such fields, even minor errors can lead to major issues, making the high precision of laser cutting technology indispensable.

High Speed Increases Productivity

Another notable advantage of laser cutting technology is its high speed. Laser cutting machines can complete complex cutting tasks in a very short time, greatly reducing production cycles. This speed advantage is particularly evident in mass production.

For instance, in the electronics manufacturing industry, the cutting process of circuit boards is complex and delicate. Laser cutting technology not only increases cutting speed but also ensures high precision, thereby enhancing overall productivity. High speed means that companies can complete more orders in a shorter time, improving market responsiveness.

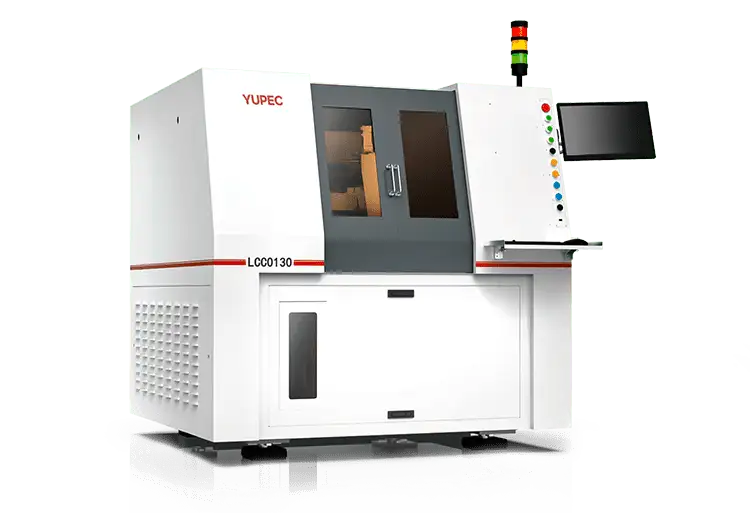

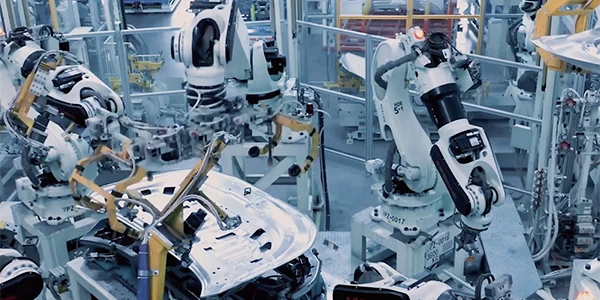

Automation Enhances Overall Efficiency

The integration of modern laser cutting technology with automation further enhances production efficiency. Automated laser cutting systems can operate continuously for 24 hours, significantly increasing the utilization rate of production lines. At the same time, automation reduces human operational errors, improving product consistency and quality.

By integrating advanced control software and sensors, laser cutting systems can monitor and adjust the cutting process in real-time to ensure optimal cutting results. For example, intelligent manufacturing systems can automatically adjust cutting parameters based on material thickness and characteristics, achieving the best cutting effect. This not only improves production efficiency but also reduces resource waste and energy consumption.

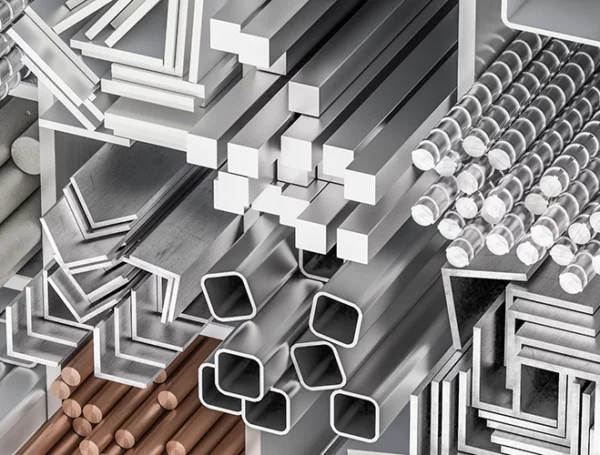

Flexibility Brings Broad Applications

The high flexibility of laser cutting technology allows it to excel in cutting various materials and thicknesses. Whether it’s metal, plastic, wood, or composites, laser cutting can deliver precise results. This flexibility enables laser cutting technology to meet diverse manufacturing needs, significantly enhancing the adaptability and versatility of production lines.

In industries such as furniture manufacturing, advertising sign production, and medical devices, laser cutting technology has a wide range of applications. Companies can quickly adjust their production lines based on market demand to produce products of different specifications and shapes, meeting customers’ personalized needs.

Energy Efficiency and Environmental Protection Promote Sustainable Development

While enhancing production efficiency, laser cutting technology also demonstrates significant advantages in energy efficiency and environmental protection. Compared to traditional cutting methods, laser cutting consumes less energy and does not produce large amounts of waste and harmful gases. This not only reduces production costs but also minimizes the negative impact on the environment, helping the manufacturing industry achieve sustainable development goals.

By reducing energy consumption and waste production, laser cutting technology helps companies lower their carbon footprint, aligning with modern society’s requirements for environmental protection and sustainability. For instance, in metal processing, laser cutting technology can reduce waste to a minimum, bringing material utilization close to 100%, thereby significantly lowering production costs and environmental burdens

Conclusion

With its high precision, high speed, high flexibility, and automation advantages, laser cutting technology significantly enhances manufacturing efficiency. In the fierce market competition, companies that master and apply laser cutting technology will gain obvious advantages in improving product quality, reducing production costs, and meeting market demands. Looking ahead, as laser technology continues to advance, the application of laser cutting in manufacturing will become more widespread, creating more value and opportunities for companies.

The progress of laser cutting technology not only drives the development of the manufacturing industry but also provides companies with more innovation and competition opportunities. In the global market, companies with advanced laser cutting technology will have stronger competitiveness and broader development prospects. As technology continues to advance, laser cutting technology will play an increasingly important role in the future of manufacturing, bringing more possibilities and development space for companies.