Table of Contents

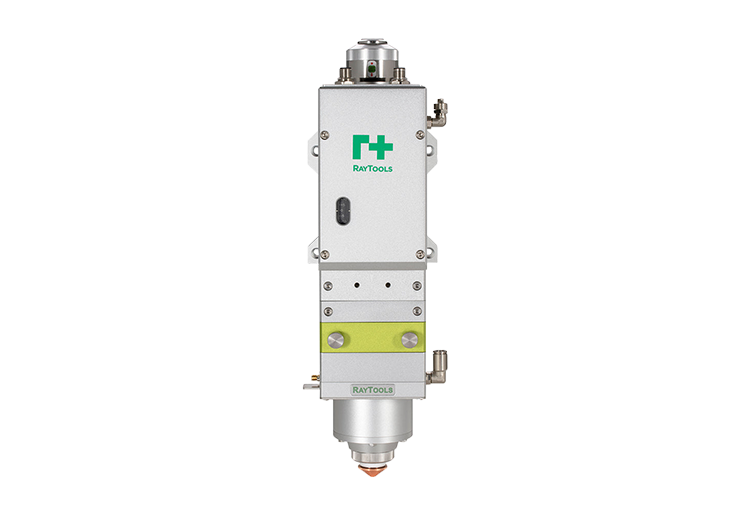

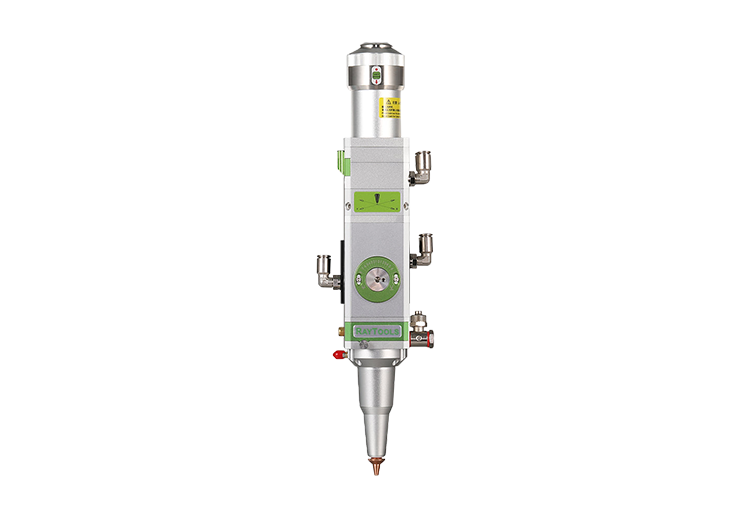

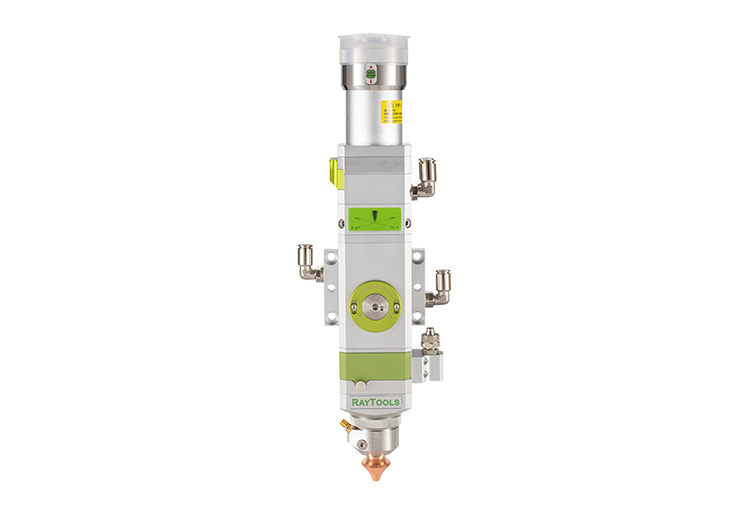

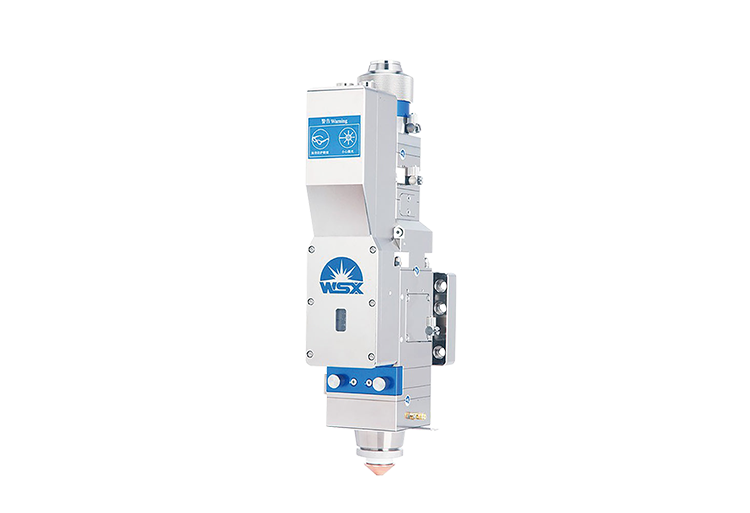

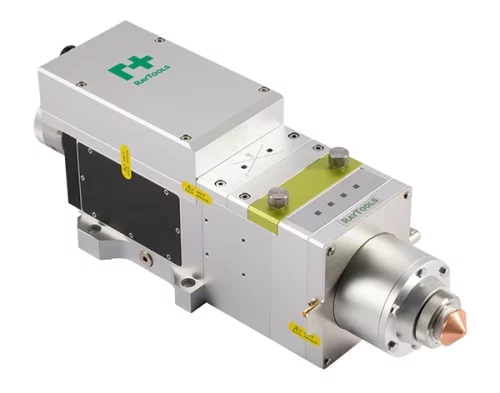

A laser cutting machine is a type of processing equipment that utilizes a high-energy laser beam to cut materials, and the cutting head is one of its key components. The cutting head of a laser cutting machine is the laser output device, composed of a nozzle, a focusing lens, and a focusing tracking system. The cutting head of a laser cutting machine moves according to the set cutting trajectory, but adjustments are needed for different materials, thicknesses, and cutting methods. The quality of the cutting head directly affects the cutting effect and production efficiency of the laser cutting machine. Therefore, when choosing a laser cutting machine, attention should be paid to the selection of the cutting head. So, what factors should be considered when choosing the right laser cutting head? Below are some key factors to focus on when selecting a cutting head.

1. Type and Structure of the Cutting Head

Laser cutting heads come in various types and structures, each suitable for different materials and cutting requirements. When choosing a laser cutting machine, it’s essential to understand the type and structure of the cutting head being used and select the appropriate one based on your processing needs. For example, cutting thick metal materials requires a cutting head with higher power and larger nozzle diameter, while cutting thin metal or non-metal materials requires a high-precision cutting head.

2. Optical Parameters

The optical parameters are crucial factors affecting the performance of the laser cutting head. These parameters include collimation focal length, focusing focal length, spot size, effective working focal length, adjustable focusing range, etc. They are closely related to the cutting process of the laser cutting head. Whether different cutting processes can be effectively implemented or whether the laser cutting head can meet the requirements of a particular process depends on appropriate optical parameters. When selecting a laser cutting head, priority should be given to various optical parameters.

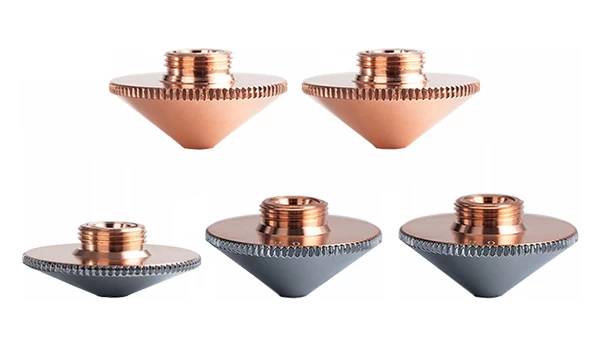

3. Nozzle Design

The design of the cutting head’s nozzle is one of the key factors affecting cutting efficiency. The nozzle design needs to consider factors such as the focusing mode of the laser beam, nozzle material, and nozzle diameter. A well-designed laser nozzle can effectively control the shape and size of the laser beam, improving cutting accuracy and speed. Therefore, when selecting a laser cutting machine, attention should be paid to choosing a cutting head with a reasonable nozzle design.

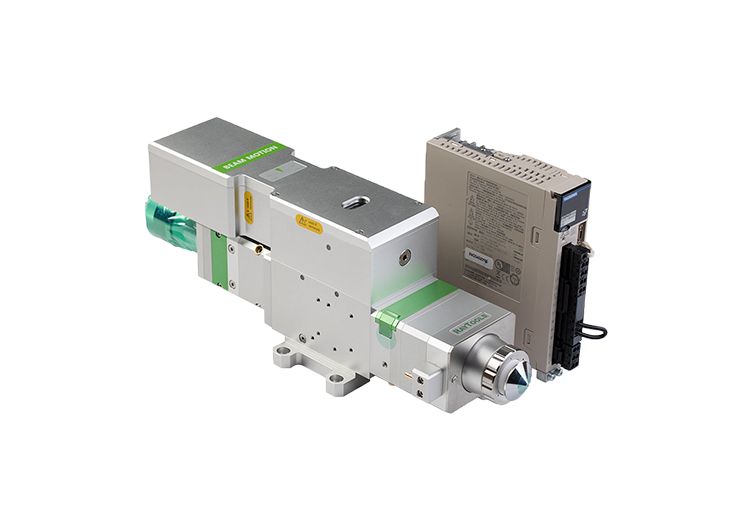

4. Compatibility

Laser cutting heads need to work with various devices such as laser cutting machines, chiller units, lasers, etc. The compatibility of a laser cutting head is determined by the strength of the manufacturer. A laser cutting head with good compatibility has strong collaborative capabilities and does not affect the performance of other equipment, effectively improving work efficiency.

5. Power and Heat Dissipation

When considering choosing a laser cutting head, power and heat dissipation are crucial factors. The power of the laser cutting head determines its cutting ability, i.e., the thickness of materials it can cut and the speed. A higher-power cutting head can more easily penetrate thicker materials, but it also requires a more effective heat dissipation system to avoid overheating and damaging the equipment. Overheating can lead to a decrease in the performance of the laser cutting head or even damage, affecting cutting quality and stability. Therefore, choosing a laser cutting head with a well-designed heat dissipation system is essential.

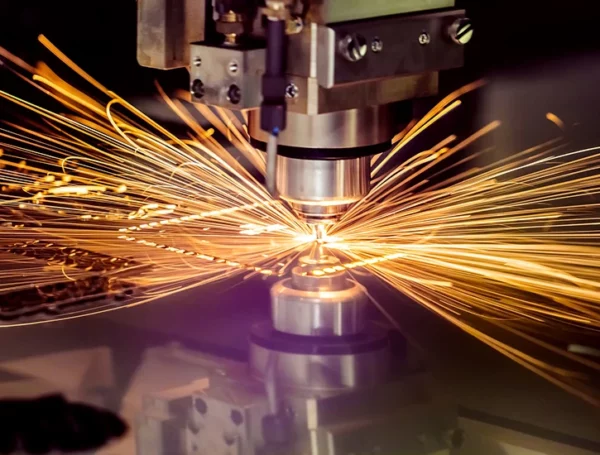

6. Cutting Accuracy

Cutting accuracy is the foundation of selecting a laser cutting head. This accuracy refers to the contour accuracy of the workpiece during cutting, not the static accuracy marked on the sample. The distinction between good and bad laser cutting heads lies in whether the accuracy will change during high-speed cutting of parts and whether the consistency of the workpiece at different positions will change.

7. Cutting Efficiency

Cutting efficiency is a critical indicator of laser cutting head performance. Cutting efficiency refers to the time taken to cut a workpiece, rather than simply looking at cutting speed. Cutting efficiency is affected by factors such as power and speed matching, cutting quality and stability, automation and intelligence, cutting head design and material, etc. Considering these factors comprehensively can improve cutting efficiency, increase production efficiency, and reduce costs.

8. Durability and Maintenance Costs

The durability and maintenance costs of the cutting head are also factors to consider when choosing a laser cutting machine. Generally, cutting heads with good quality have longer service life and lower maintenance costs. When selecting a laser cutting machine, it is necessary to understand the durability and maintenance costs of the cutting head and make comprehensive considerations to choose a cutting head with high cost performance.

Conclusion

In summary, when choosing a laser cutting head, it is necessary to consider the above factors comprehensively and make appropriate choices based on your processing needs and budget. It is also recommended to conduct sufficient market research and product comparisons before making a decision, understand the performance characteristics and user evaluations of different brands and models of cutting heads, in order to make a more informed decision. Choosing the right laser cutting head can not only improve cutting efficiency and accuracy but also reduce production and maintenance costs, bringing greater competitive advantages to the enterprise.